Project Description

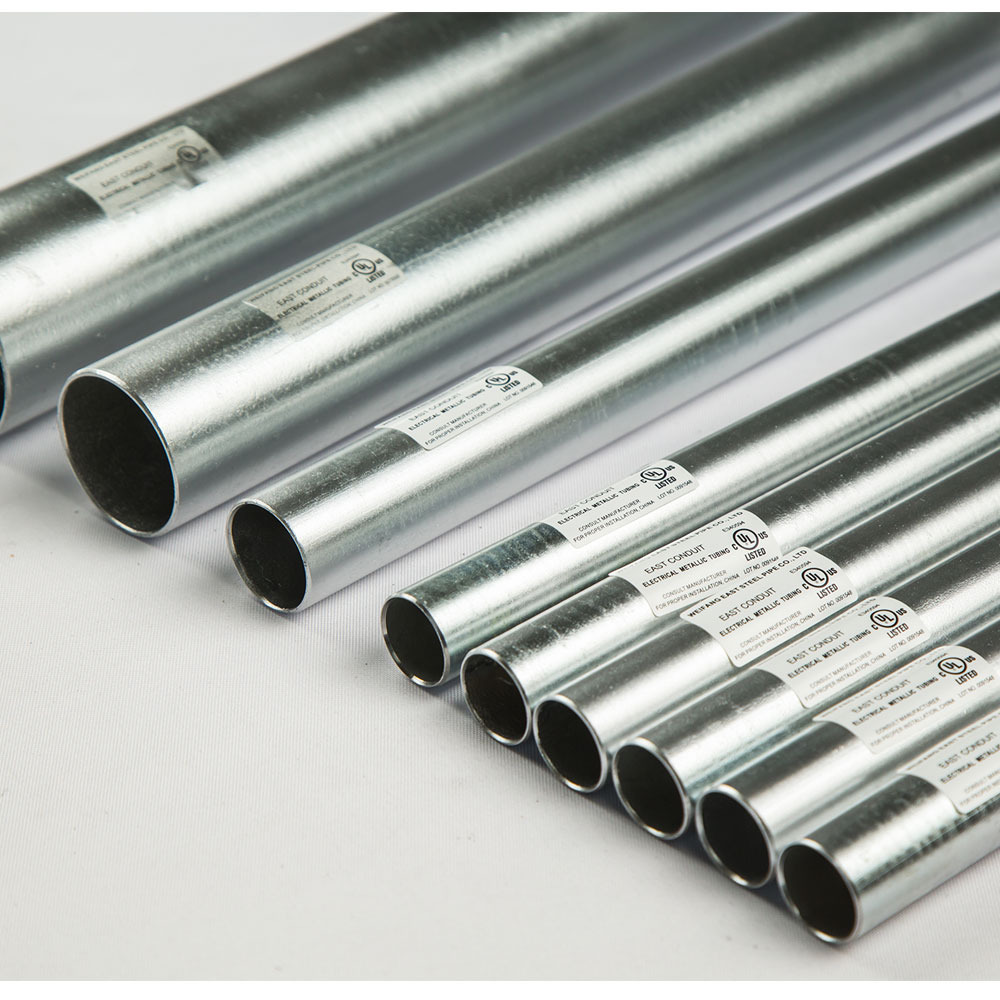

East Conduit’s IMC Conduit (UL1242) has excellent protection, strength, safety and ductility for your wiring works.

East Conduit IMC conduit is manufactured with high-strength steel coil, and produced by the electric resistance welding process according to the standard of ANSI C80.6,UL1242.

East Conduit IMC conduit is zinc coated both inside and outside, the clear post-galvanizing coating to provide further protection against corrosion, so it offers corrosion protection for installation in dry, wet, exposed, concealed or hazardous location.

East Conduit IMC Conduit is produced in normal trade sizes from 1/2” to 4” in standard lengths of 10feet(3.05m). Both ends threaded according to the standard of ANSI/ASME B1.20.1 ,coupling supplied on one end,color-coded thread protector on the other end for quick identification of the conduit size.

Features and Benefits

Consistent Quality – The weight of IMC about 30% less than rigid steel conduit ,it is also manufactured for long life; it is durable, strong, and suitable for harshest environmental conditions. The steel is welded to ensure quality standards are met strictly. The inside surface of the pipe is obstruction-free and extra smooth, making wire pulling and pushing easy and reducing friction between wall and wire. The product is easy to cut, form and join.

Lower Life-cycle costs – East conduit resists cracking, flaking, peeling, impact, and damage from severe bending. Its physical and mechanical properties ensure that the pipe has an extended life cycle and helps for usage or storage without trouble in quality.

Protection from Environmental Damage and Mechanical Use – the thorough inside and outside zinc coating of East Conduit provides enhanced, second to none corrosion protection.

Specifications

East Conduit IMC conduit is manufactured in accordance with the latest edition of the following:

⊙ American National Standards Institute (ANSI®)

⊙ American National Standard for Rigid Steel Tubing (ANSI® C80.6)

⊙ Underwriters Laboratories Standard for Rigid Steel Tubing (UL1242)

⊙ National Electric Code® 250.118(3)

Dimension and Weight Chart (IMC)

| Trade Size | Nominal Wt. per 100Ft(30.5M) | Nominal Outside Diameter | Nominal Inside Diameter | Nominal Wall Thickness | |||||

| U.S. | Metric | Lbs | Kg | In. | mm | In. | mm | In. | mm |

| 1/2 | 16 | 62 | 28.12 | 0.815 | 20.70 | 0.660 | 16.76 | 0.078 | 1.97 |

| 3/4 | 21 | 84 | 38.10 | 1.029 | 26.26 | 0.869 | 22.07 | 0.083 | 2.10 |

| 1 | 27 | 119 | 53.98 | 1.290 | 32.77 | 1.105 | 28.07 | 0.093 | 2.35 |

| 1-1/4 | 35 | 158 | 71.67 | 1.638 | 41.59 | 1.448 | 36.77 | 0.095 | 2.41 |

| 1-1/2 | 41 | 194 | 88.00 | 1.883 | 47.82 | 1.683 | 42.74 | 0.100 | 2.54 |

| 2 | 53 | 256 | 116.12 | 2.360 | 59.93 | 2.150 | 54.60 | 0.105 | 2.67 |

| 2-1/2 | 63 | 441 | 200.04 | 2.857 | 72.57 | 2.557 | 64.95 | 0.150 | 3.81 |

| 3 | 78 | 543 | 246.30 | 3.476 | 88.29 | 3.176 | 80.67 | 0.150 | 3.81 |

| 3-1/2 | 91 | 629 | 285.31 | 3.971 | 100.86 | 3.671 | 93.24 | 0.150 | 3.81 |

| 4 | 103 | 700 | 317.52 | 4.466 | 113.44 | 4.166 | 105.82 | 0.150 | 3.81 |

Packing Schedule(America Standard)

| Trade Size | Protector Color | Quantity in Bundle | Quantity per Master Bundle | Weight/Lift | ||||||

| U.S. | Metric | Feet | Meters | PCS | BD’s | Feet | Meters | LBS | KG | |

| 1/2 | 16 | Yellow | 100 | 30.5 | 350 | 35 | 3500 | 1067 | 2170 | 984.3 |

| 3/4 | 21 | Green | 50 | 15.2 | 250 | 50 | 2500 | 762 | 2100 | 952.6 |

| 1 | 27 | Orange | 50 | 15.2 | 170 | 34 | 1700 | 518 | 2023 | 917.6 |

| 1-1/4 | 35 | Green | – | – | 135 | – | 1350 | 411 | 2133 | 967.5 |

| 1-1/2 | 41 | Yellow | – | – | 110 | – | 1100 | 335 | 2134 | 968.0 |

| 2 | 53 | Orange | – | – | 80 | – | 800 | 244 | 2048 | 929.0 |

| 2-1/2 | 63 | Yellow | – | – | 37 | – | 370 | 113 | 1632 | 740.1 |

| 3 | 78 | Orange | – | – | 30 | – | 300 | 91 | 1629 | 738.9 |

| 3-1/2 | 91 | Yellow | – | – | 24 | – | 240 | 73 | 1510 | 684.8 |

| 4 | 103 | Orange | – | – | 24 | – | 240 | 73 | 1680 | 762.0 |

Applicable Tolerances:

Length: 10Ft (3.05m) ± ¼” (±6mm).

UL Certificate No.: E499791