Project Description

The coated pipes are composed of three functional components: a high-performance fusion bonded epoxy (FBE), followed by a copolymer adhesive and an outer layer of polyethylene which provides tough and durable protection.

Widely used as preservative pipeline. Such as:

Application:

- Water supply pipeline

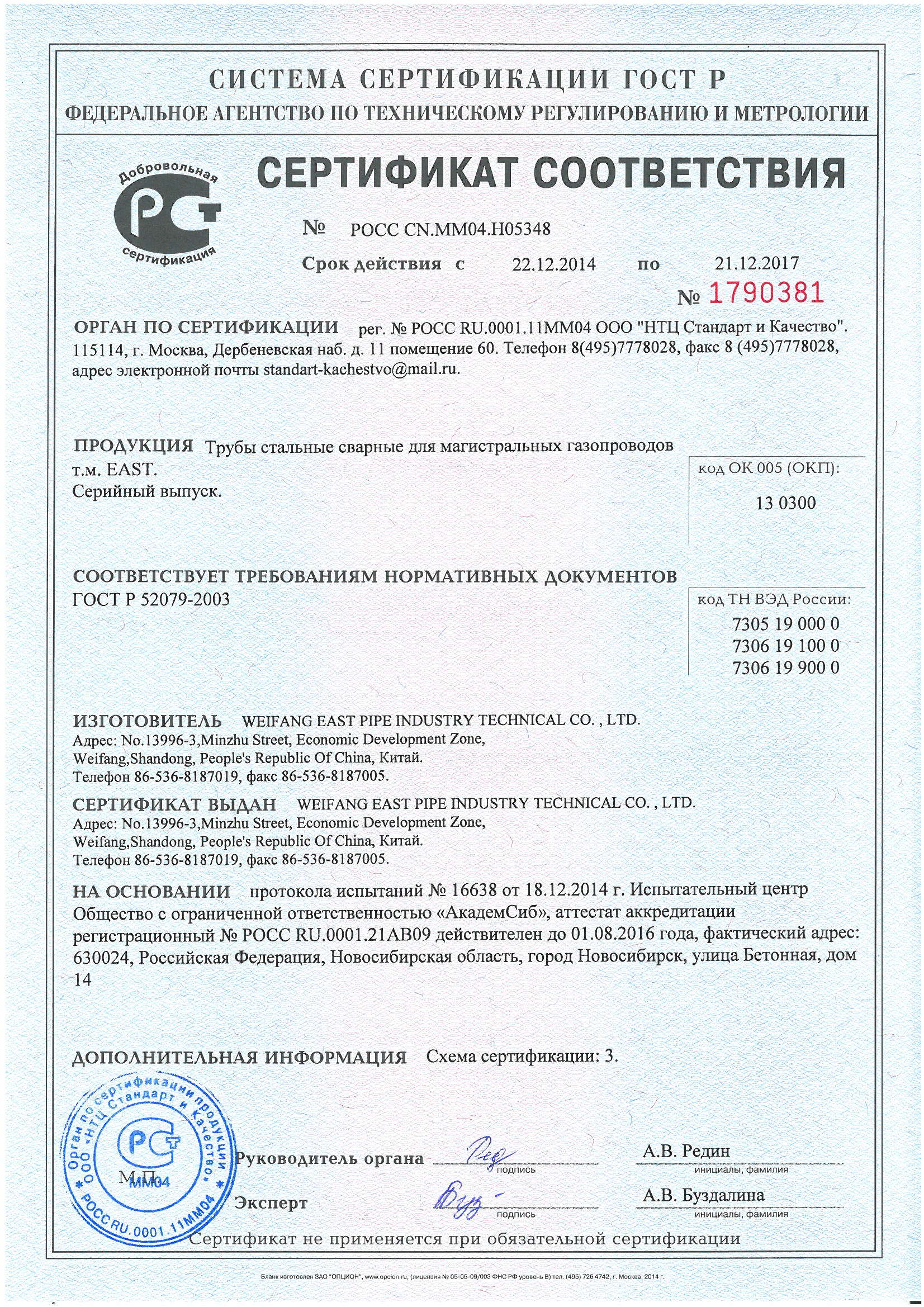

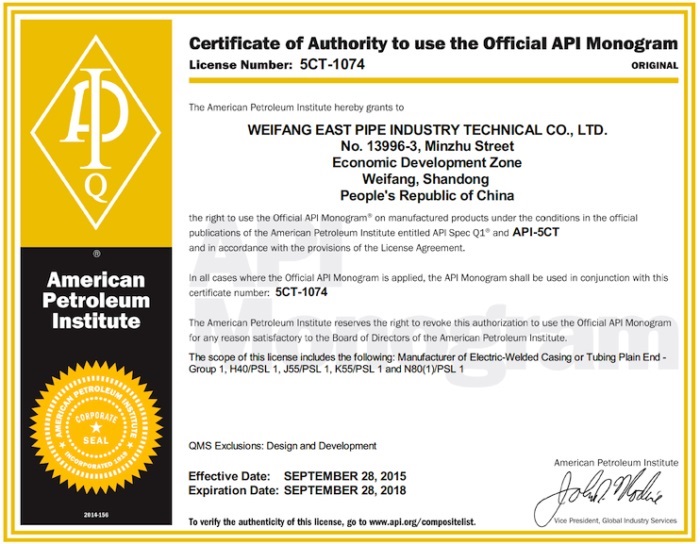

- Gas transportation pipe line

- Oil transportation pipe line

- Mine, power, chemical transportation pipe line

Specification:

- O.D.: 159mm ~ 1220mm

- Coating Standard: DIN30670

- Packing: Waterproof Paper wrapped, Steel Strips bundled

2PE/3PE Coating Characteristics

| NO. | Item | Property data | Test way | ||

| two laye | three layer | ||||

| 1 | Detach strength(N/cm) | 20℃±5℃ | ≥70 | ≥100 | SY/T0413-2002 |

| 50℃±5℃ | ≥35 | ≥70 | |||

| 2 | Cleaning of the cathode(65℃,48h)(mm) | ≤8 | SY/T0413-2002 | ||

| 3 | Impact test(J/mm) | ≥8 | SY/T0413-2002 | ||

| 4 | Bending strength(2.5°-30℃±5℃) | No crack of polythene | SY/T0413-2002 |

2PE/3PE Coating Thickness Requirements

| N.B | Epoxy powder coating | Adhesive(um) | Min wall thickness of anticorrosive coating(mm) | ||

| (mm) | (mm) | two layer | three layer | usual grade | strengthen grade |

| ≤100 | ≥80 | 1.8 | 2.5 | ||

| 250<DN≤250 | 200-400 | 170-250 | 2 | 2.7 | |

| 250<DN≤500 | 2.2 | 2.9 | |||

| 500<DN≤800 | 2.5 | 3.2 | |||

| DN≥800 | 3 | 3.7 | |||

3PE Coating Line:

Liaoning Datang Group Coal-based Natural Gas Project.

Baoji Cigarette Factory Water Networks