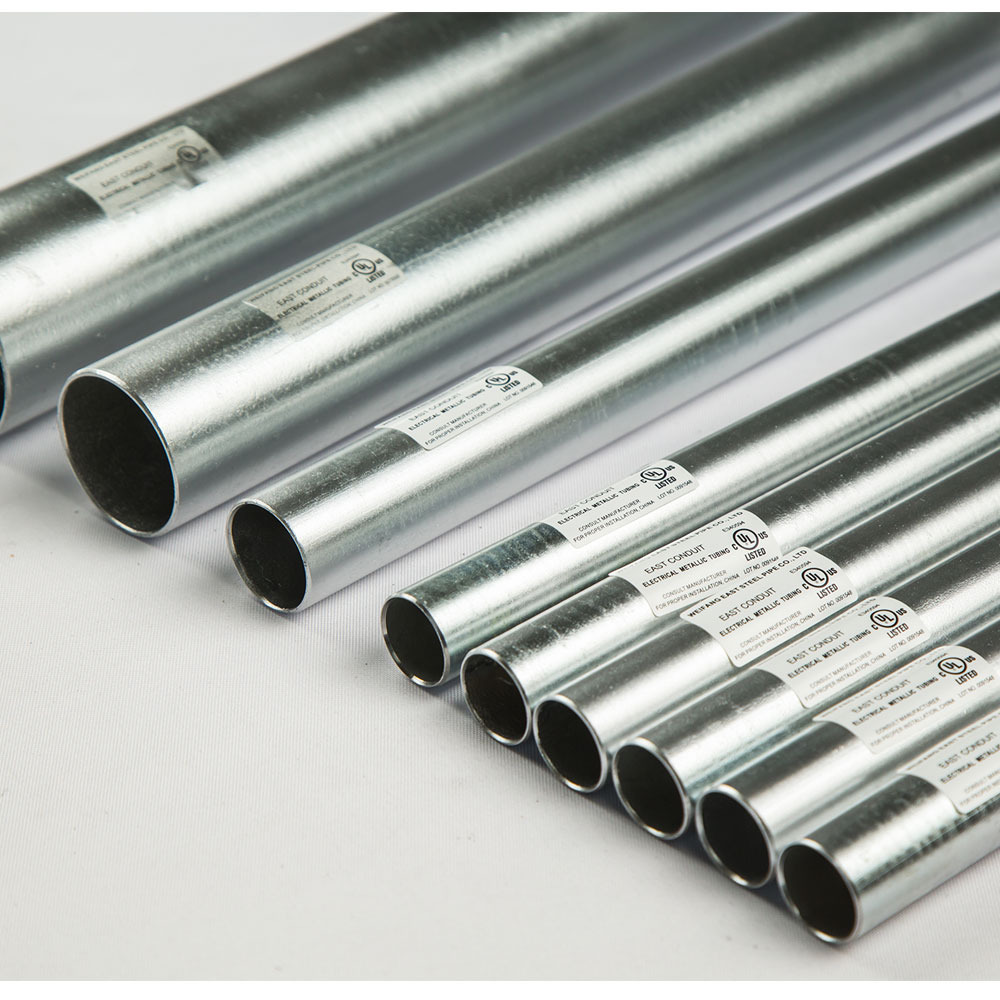

Galvanized Conduit – Optimization for Sulphate Galvanizing

The biggest advantage of sulfate galvanizing is that the current efficiency is as high as 100% and the deposition rate is fast, which is unmatched by other galvanizing processes. Because the crystallization of the coating is not fine enough, the dispersion ability and deep plating ability are poor, so it is only suitable for electroplating of pipes and wires with simple geometric shapes. The sulfate electroplating galvanized iron alloy process optimizes the traditional sulfate galvanizing process, only retaining the main salt zinc sulfate, and discarding the rest of the components.

An appropriate amount of iron salt is added to the new process formula to make the original single metal coating form a zinc-iron alloy coating. The reorganization of the process not only carried forward the advantages of high current efficiency and fast deposition rate of the original process, but also greatly improved the dispersion ability and deep plating ability. In the past, complex parts could not be plated, but now simple and complex parts can be plated, and the protective performance 3 to 5 times higher than single metal. Production practice has proved that for continuous electroplating of wires and pipes, the coating grains are finer and brighter than the original ones, and the deposition rate is fast.

The coating thickness reaches the requirement within 2 to 3 minutes. Galvanized Conduit – Conversion of Sulphate Galvanizing Only zinc sulfate, the main salt of sulfate galvanizing, is reserved for sulfate electroplating galvanized iron alloys, and other components such as aluminum sulfate, alum (aluminum potassium sulfate), etc. can be added to the plating solution to form insoluble hydroxide precipitation. Remove; for organic additives, add powdered activated carbon to absorb and remove.

Tests have shown that aluminum sulfate and potassium aluminum sulfate are difficult to remove completely at one time, and have an impact on the brightness of the coating, but it is not serious and can be consumed along with it. At this time, the brightness of the coating can be restored. Replenishment of component content is required to complete the conversion. Galvanized Conduit – fast deposition rate, excellent protection performance The current efficiency of sulfate electroplating zinc-iron alloy process is as high as 100%, and the deposition rate is unparalleled by any galvanizing process. The running speed of the fine tube is 8-12 m/min, and the average thickness of the coating is 2m/min, which is difficult for continuous galvanizing. achieved.

The coating is bright and delicate. According to the national standard GB/T10125 “artificial atmosphere test-salt spray test” method, after 72 hours, the coating is intact and unchanged; after 96 hours, a small amount of white rust appears on the surface of the coating.